Executive Summary

For the past four weeks, I have discussed the inherent problems of operating machinery with obsolete control systems—from the hidden financial burdens and operational bottlenecks to the severe, unseen safety risks.

Now, I want to pivot towards solutions. This week, my focus is on the strategy of a control system retrofit.

I will demonstrate that a retrofit is not just a repair; it is a comprehensive revitalisation that addresses all the core issues of obsolescence, extends the life of valuable assets, improves efficiency, and enhances safety—often at a fraction of the cost and lead time of purchasing new equipment.

1. The Dilemma: Replace or Revitalise?

Once the problems of obsolete control systems become apparent—frequent breakdowns, slow production, or safety concerns—many business leaders face a significant dilemma: should I invest in a brand-new machine, or can I somehow salvage my existing asset?

Purchasing new equipment often comes with a hefty price tag, long lead times for delivery and installation, and the significant disruption of removing old machinery and integrating new systems.

For many businesses, particularly in developing economies, this is simply not a viable option.

My research indicates there is a compelling alternative that offers a robust solution without the prohibitive costs and delays of a full replacement: the control system retrofit.

2. What is a Control System Retrofit?

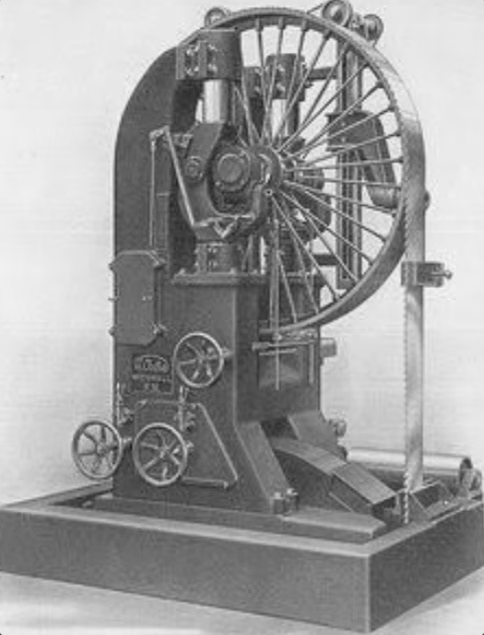

A control system retrofit involves replacing the outdated “brain” of a machine—its old PLCs, HMIs, drives, and associated wiring—with modern, state-of-the-art components.

This is not just a swap; it is an opportunity to redesign and enhance the machine’s operational intelligence.

Think of it like upgrading an old car with a brand-new, more powerful, and fuel-efficient engine, along with a modern dashboard and navigation system.

The chassis and body remain, but the core functionality is entirely revitalised. The machine retains its proven mechanical integrity while gaining all the advantages of contemporary control technology.

3. The Compelling Advantages of a Retrofit

My analysis shows that a well-executed control system retrofit addresses the very issues I have highlighted in previous articles:

3.1. Significant Cost Savings (Addressing TCO)

A retrofit typically costs a fraction of what a new machine would.

You leverage the existing mechanical structure, which is often still perfectly sound.

This avoids the massive capital outlay and reduces the depreciation associated with new equipment.

By improving reliability, you also drastically cut down on the unpredictable costs of emergency repairs and sourcing obsolete spares, directly impacting the Total Cost of Ownership (TCO) https://tsikdem.co.zw/the-hidden-cost-of-old-machinery-more-than-just-the-purchase-price/.

3.2. Enhanced Efficiency and Productivity (Overcoming Bottlenecks)

Modern control systems are faster, more precise, and offer advanced capabilities that old systems simply could not. This translates directly into:

- Consistent Cycle Times: Eliminating the erratic performance I described in my previous bottleneck report https://tsikdem.co.zw/bottleneck-of-outdated-control-systems/.

- Reduced Downtime: Modern components are more reliable, and their diagnostics are clearer, allowing for quicker troubleshooting and maintenance.

- Optimized Performance: Machines can run closer to their mechanical limits, increasing throughput and reducing scrap rates.

3.3. Improved Safety and Compliance (Eliminating Unseen Risks)

This is one of the most critical benefits. A retrofit allows you to integrate modern safety PLCs, safety relays, and up-to-date safety interlocks.

This means the machine can be brought into compliance with current safety standards, mitigating the “unseen risks” I discussed in Week 4 – https://tsikdem.co.zw/the-unseen-risk-why-obsolete-control-systems-threaten-safety-and-compliance. Operators can work with greater confidence, knowing the machine’s safety systems are robust and reliable.

3.4. Future-Proofing and Connectivity

Modern control systems are designed for the future. They offer:

- Connectivity: Seamless integration with plant-wide data acquisition systems and higher-level manufacturing execution systems (MES).

- Long-Term Support: Access to readily available spare parts, manufacturer support, and a broader pool of skilled technicians for many years to come.

- Flexibility: Modern systems are easier to reprogram and adapt to new product requirements or process changes.

4. Conclusion: A Strategic Investment in Longevity

My research firmly supports the argument that a control system retrofit is a powerful and strategic investment.

It is a method not only to solve existing problems but also to proactively future-proof valuable machinery.

By embracing this approach, businesses can extend the productive life of their assets, improve operational metrics, and ensure a safer working environment—all while making a smart financial decision.

Next week, I will delve deeper into the specific technologies that make this transformation possible, focusing on: “From Analog to Digital: The Advantages of Modern PLCs and HMIs.”